Crankshaft chinzvimbo chinzwa

Zviri mukati

Iyo crankshaft sensor inopa kutonga kubva kune injini ECU yechinzvimbo chemechani chikamu chinotarisirwa kushanda kweiyo jekiseni remafuta. Kana iyo DPKV ikakundikana, inoongororwa nerubatsiro rwevaongorori vakakosha vanoshanda pamusimboti weohmmeter. Muchiitiko chekuti kupikisa kwemazuva ano kuri pasi pezita rezita, mutongi achada kuchinjwa.

Chii chinokonzera uye iyo crankshaft sensor inoshanda sei?

Iyo crankshaft chinzvimbo sensor inosarudza nguva chaiyo iyo mafuta anofanirwa kutumirwa kune yemukati combustion injini (ICE) masilinda. Mumagadzirirwo akasiyana, iyo DPKV ine basa rekudzora kurongeka kwekufanana kwemafuta anopihwa nemajekiseni.

Mabasa eiyo crankshaft sensor ndeyekunyoresa uye kuendesa iyo inotevera data kumakombuta:

- kuyera nzvimbo ye crankshaft;

- nguva iyo mapistoni anopfuura BDC neTDC mumasilinda ekutanga uye ekupedzisira.

Iyo PKV sensor inogadzirisa zvinotevera zviratidzo:

- huwandu hwemafuta anouya;

- nguva yekupihwa peturu;

- camshaft angle;

- nguva yekudzima moto;

- nguva uye nguva yekushanda kwevhavhavha yeadsorption.

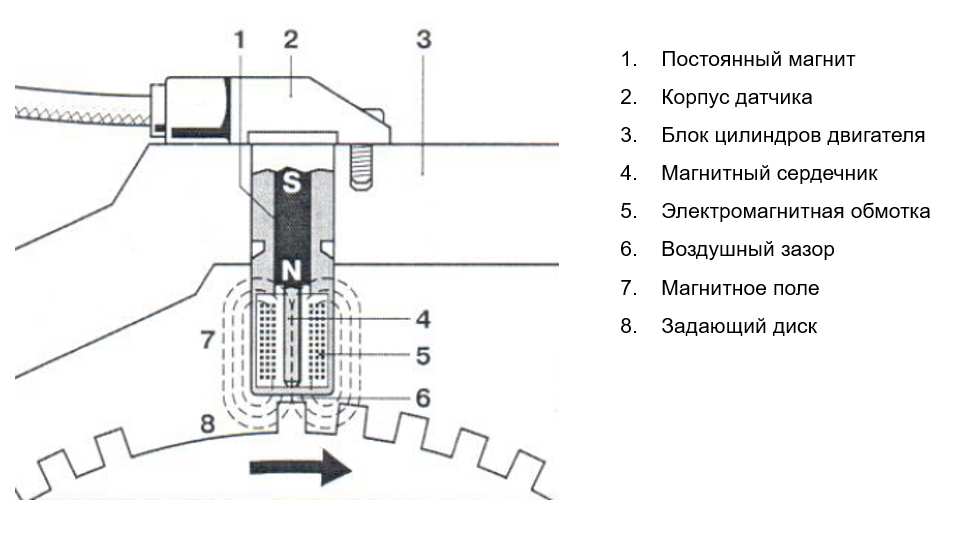

Nheyo yekushanda kweiyo nguva sensor:

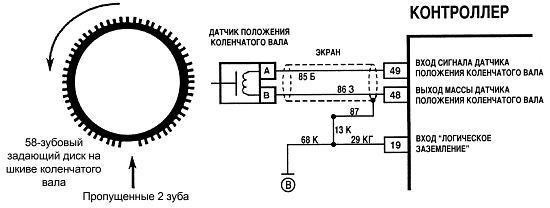

- Iyo crankshaft ine dhisiki ine mazino (kutanga uye zeroing). Apo gungano rinotenderera, magnetic field inotungamirirwa kumazino kubva kuPKV sensor, ichiita pairi. Shanduko dzinorekodhwa nenzira yemapulses uye ruzivo rwunoendeswa kumakombuta: nzvimbo ye crankshaft inoyerwa uye nguva iyo piston inopfuura nepamusoro uye pasi yakafa nzvimbo (TDC neBDC) yakanyorwa.

- Kana iyo sprocket ichipfuura crankshaft yekumhanyisa sensor, inoshandura rudzi rwekuwedzera kuverenga. Nechikonzero ichi, ECU iri kuyedza kudzoreredza kushanda kwakajairika kwe crankshaft.

- Kubva pane zvakagamuchirwa pulses, pa-bhodhi komputa inotumira chiratidzo kune inodiwa masisitimu emotokari.

DPKV mudziyo

Crankshaft sensor dhizaini:

- aluminium kana plastiki kesi ine cylindrical chimiro chine chinhu chakavanzika, kuburikidza iyo chiratidzo chinotumirwa kune komputa;

- tambo yekukurukurirana (magnetic circuit);

- drive unit;

- sealant;

- winding;

- injini gomo bracket.

Tafura: mhando dze sensors

| zita | tsananguro |

| Magnetic sensor

| Iyo sensor ine magineti echigarire uye yepakati mhepo, uye iyi mhando yemutongi haidi yakasarudzika magetsi. Iyo inductive yemagetsi mudziyo inodzora kwete chete chinzvimbo che crankshaft, asiwo kumhanya. Inoshanda nemagetsi anoitika kana zino resimbi (tag) richipfuura nepakati pemagineti. Izvi zvinogadzira chiratidzo chekupuruzira chinoenda kuECU. |

| Optical Switch

| Iyo optical sensor inosanganisira inogamuchira uye LED. Kudyidzana newachi dhisiki, inovhara kuyerera kwemaziso kunopfuura pakati peanogamuchira neiyo LED. Iyo transmitter inoona kukanganisika kwechiedza. Kana iyo LED ichipfuura nepakati penzvimbo ine mazino akasakara, inogamuchira inopindura kune pulse uye inoita kuwiriranisa neECU. |

| Horo Sensor

| Iyo sensor dhizaini inosanganisira:

MuHoro mhedzisiro crankshaft sensor, ikozvino inoyerera sezvainoswedera kune inochinja magineti. Dunhu renzvimbo yesimba rinovhura kana richipfuura munzvimbo dzine mazino akasakara uye chiratidzo chinoendeswa kune yemagetsi injini control unit. Inoshanda kubva kune yakazvimirira magetsi sosi. |

Sensor iri kupi?

Nzvimbo ye crankshaft chinzvimbo sensor: padyo ne diski pakati pealternator pulley uye flywheel. Nokuda kwekusununguka kwekusununguka kune-on-board network, tambo yakareba 50-70 cm inopiwa, iyo pane zvibatanidza zvekiyi. Kune ma spacers pachigaro chekuisa gap 1-1,5mm.

Zviratidzo uye zvinokonzera malfunctions

Zviratidzo zveDPKV yakaputsika:

- injini haina kutanga kana kungomira pakarepo mushure mechinguva;

- hapana sparks;

- ICE detonation inoitika nguva nenguva pasi pemitoro ine simba;

- isina kugadzikana idle speed;

- injini simba uye motokari dynamics zvakaderedzwa;

- pakuchinja modes, shanduko inongoerekana yaitika muhuwandu hwekuchinja kunoitika;

- tarisa chiedza cheinjini pane dashboard.

Zviratidzo zvinonongedza kune zvikonzero zvinotevera nei iyo PCV sensor ingave isina mhosva:

- kupfupika kwedunhu pakati pekutenderera kutenderera, zvinogona kukanganisa chiratidzo nezve chinzvimbo chepiston paBDC neTDC;

- tambo yekubatanidza DPKV kuECU yakakuvadzwa - iyo pa-bhodhi komputa haigamuchire chiziviso chakakodzera;

- kukanganisa kwemeno (scuffs, chips, cracks), injini inogona kusatanga;

- kupinda kwezvinhu zvekune dzimwe nyika pakati pezino pulley uye counter kana kukuvadzwa paunenge uchishanda muimba yejini zvinowanzokonzera kusashanda kweDPKV.

Matambudziko nekutanga injini

Kusiyana kwekutadza kushanda kwe crankshaft sensor inokanganisa kushanda kweinjini yekupisa yemukati:

- Injini haina kutanga. Kana kiyi yekubatidza ichitenderedzwa, chinotangisa chinotenderedza injini uye pombi yemafuta inorira. Chikonzero ndechekuti injini ECU, isina kugamuchira chiratidzo kubva kune crankshaft chinzvimbo sensor, haigone kuburitsa murairo nemazvo: papi yemasilinda ekutanga uye painovhura muromo.

- Injini inopisa kusvika kune imwe tembiricha uye inomira kana kuti haitangi muchando chakanyanya. Pane chikonzero chimwe chete - microcrack muPKV sensor winding.

Kusagadzikana kushanda kweinjini munzira dzakasiyana siyana

Izvi zvinoitika kana DPKV yakasvibiswa, kunyanya kana machipisi esimbi kana mafuta apinda mairi. Kunyangwe kukanganiswa kudiki pane iyo magineti microcircuit yenguva sensor inoshandura kushanda kwayo, nekuti iyo counter inonzwa zvakanyanya.

Kuvapo kwe detonation yemota nekuwedzera mutoro

Chikonzero chinonyanya kukosha ndechekukundikana kweiyo metering device, pamwe chete ne microcrack mumhepo inoputika, iyo inokotama panguva yekudengenyeka, kana kuputika kweimba, umo unyoro hunopinda.

Zviratidzo zvekugogodza injini:

- kutyorwa kwehunyoro hwekuita kwekupisa kwemafuta-mhepo musanganiswa mumasilinda ejini inopisa mukati;

- kusvetuka pane anogamuchira kana exhaust system;

- kukundikana;

- kuderedzwa kwakajeka kwesimba rejini.

Yakaderedzwa injini simba

Simba reinjini rinodonha kana musanganiswa wemafuta-mweya usina kupihwa nenguva. Chikonzero chekusashanda ndiko delamination yekuvhunduka uye kutama kweyeredzi ine mazino maererano nepulley. Simba reinjini rakaderedzwa zvakare nekuda kwekukuvadzwa kumhepo kana imba ye crankshaft chinzvimbo mita.

Nzira yekutarisa sei crankshaft sensor iwe pachako?

Iwe unogona kuzvimiririra kuongorora hutano hweDPKV uchishandisa:

- ohmmeter;

- oscillograph;

- yakaoma, uchishandisa multimeter, megohmmeter, network transformer.

Zvinokosha kuziva

Usati watsiva iyo yekuyeresa mudziyo, inokurudzirwa zvakare kuita yakakwana komputa diagnostics yeinjini yekupisa yemukati. Zvadaro kuongorora kwekunze kunoitwa, kubvisa kusvibiswa kana kukanganisa kwemagetsi. Uye chete mushure meizvozvo vanotanga kuongorora nemidziyo yakakosha.

Kuongorora ne ohmmeter

Usati waenderera nekuongorora, dzima injini uye bvisa sensor yenguva.

Nhanho-nhanho mirayiridzo yekudzidza DPKV ine ohmmeter kumba:

- Isa ohmmeter kuyera kuramba.

- Sarudza dhigirii rekudzivirira throttle (bata tester probes kumaterminals uye ringire).

- Kukosha kunogamuchirwa kunobva pa500 kusvika ku700 ohms.

Kushandisa oscilloscope

Iyo crankshaft chinzvimbo sensor inotariswa neinjini iri kushanda.

Algorithm yezviito uchishandisa oscilloscope:

- Batanidza muyedzi kune timer.

- Runza chirongwa pa-bhodhi komputa inotarisisa kuverenga kubva mumudziyo wemagetsi.

- Pfuura chinhu chesimbi pamberi pe crankshaft sensor kakawanda.

- Iyo multimeter yakanaka kana oscilloscope ichipindura kufamba. Kana pasina masaini paPC skrini, zvinokurudzirwa kuita kuongororwa kwakazara.

Comprehensive cheki

Kuti uite izvi, unofanirwa kuve uine:

- megger;

- network transformer;

- inductance mita;

- voltmeter (zvichida digital).

Algorithm yezviito:

- Usati watanga scan yakazara, sensor inofanira kubviswa kubva mujini, yakanyatsoshambidzwa, yakaomeswa, uye yozoyerwa. Inoitwa chete pakupisa kwekamuri, kuitira kuti zviratidzo zvive zvakanyatsojeka.

- Kutanga, iyo inductance ye sensor (inductive coil) inoyerwa. Kushandiswa kwaro kwezviyero zvenhamba kunofanira kuva pakati pe 200 ne 400 MHz. Kana kukosha kwakasiyana zvakanyanya kubva pakukosha kwakatarwa, zvingangoita kuti sensor inokanganisa.

- Tevere, iwe unofanirwa kuyera kudzivirira kwekudzivirira pakati pematerminals ecoil. Nokuda kweizvi, megohmmeter inoshandiswa, kuisa magetsi ekubuda kusvika ku500 V. Zviri nani kuita nzira yekuyera 2-3 nguva kuti uwane data yakarurama. Iyo yakayerwa insulation yekudzivirira kukosha inofanira kunge iri 0,5 MΩ. Zvikasadaro, kutadza kwekudzivirira mucoil kunogona kutsanangurwa (kusanganisira mukana weiyo pfupi dunhu pakati pekutendeuka). Izvi zvinoratidza kutadza kwemudziyo.

- Zvadaro, uchishandisa network transformer, iyo nguva disk inobviswa magineti.

Dambudziko-kupfura

Zvine musoro kugadzirisa sensor kune malfunctions akadai se:

- kupinda mukati mePKV kusvibiswa sensor;

- kuvapo kwemvura mune sensor connector;

- kuputika kwechidziviriro chekudzivirira chetambo kana sensor harnesses;

- kuchinja kwe polarity yetambo dzechiratidzo;

- hapana kubatana netambo;

- mapfupi masaini waya kune sensor pasi;

- kuderedzwa kana kuwedzera kukwira kubvumidzwa kwe sensor uye synchronizing disk.

Tafura: shanda nehurema hudiki

| Default | Zvinoreva |

|---|---|

| Kupinda mukati mePKV sensor uye kusvibiswa |

|

| Kuvapo kwemvura mune sensor connector |

|

| Yakaputsika sensor tambo nhovo kana harness |

|

| Dzosera polarity yetambo dzechiratidzo |

|

| Iyo sensor haina kubatana kune harness |

|

| Sensor masign waya dzakapfupikiswa kusvika pasi |

|

| Kuderedza kana kuwedzera kukwirisa kubvumidzwa kwe sensor uye synchronizing disk |

|

Nzira yekushandura sei crankshaft position sensor?

Akakosha nuances anofanirwa kucherechedzwa kana uchitsiva iyo DPKV:

- Usati waparadzana, zvinodikanwa kuti uise mamakisi anoratidza nzvimbo yebhaudhi maererano ne sensor, iyo DPKV pachayo, pamwe nekumaka waya uye magetsi ekubata.

- Paunenge uchibvisa uye nekuisa nyowani PKV sensor, zvinokurudzirwa kuve nechokwadi chekuti dhisiki yenguva iri mumamiriro akanaka.

- Tsiva mita ne harness uye firmware.

Kutsiva iyo PKV sensor, iwe uchada:

- mudziyo mutsva wekuyeresa;

- otomatiki tester;

- cavernometer;

- chipanera 10.

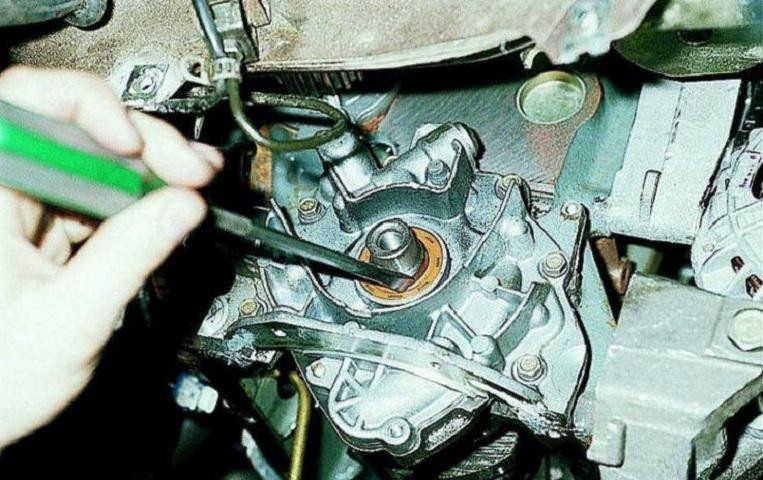

Action algorithm

Kuti uchinje iyo crankshaft chinzvimbo sensor nemaoko ako, unoda:

- Bvisa chakaburitswa.

- De-energize mudziyo wemagetsi nekubvisa terminal block kubva kune controller.

- Nechipanera, sunungura screw inogadzirisa sensor, bvisa iyo DPKV yakashata.

- Shandisa rag kuchenesa nzvimbo yekumhara yemafuta ane mafuta uye tsvina.

- Isa iyo nyowani yekudzvanya geji uchishandisa ekare fasteners.

- Ita zviyero zvekudzora zvepakati pemazino ealternator drive pulley uye sensor core uchishandisa vernier caliper. Nzvimbo yacho inofanira kuenderana nemitemo inotevera: 1,0 + 0,41 mm. Kana iyo gap iri diki (yakakura) kupfuura kukosha kwakatarwa panguva yekuyera kuyerwa, nzvimbo ye sensor inofanira kugadziriswa.

- Tarisa kuramba kweiyo crankshaft chinzvimbo sensor uchishandisa yekuzviongorora. Kune sensor inoshanda, inofanirwa kunge iri pakati pe550 kusvika 750 ohms.

- Gadzirisa komputa yerwendo kuti udzime chiratidzo cheCheck Engine.

- Batanidza iyo crankshaft chinzvimbo sensor kune network (chibatanidza chakaisirwa izvi).

- Tarisa mashandiro echishandiso chemagetsi nenzira dzakasiyana: pakuzorora uye pasi pesimba rekuita.