Ivhavha nzira yeinjini, mudziyo wayo uye musimboti wekushanda

Zviri mukati

Irovhavha yemagetsi ndeye yakananga nguva actuator, iyo inovimbisa kupihwa panguva yakakodzera yemhepo-mafuta musanganiswa kumasilinda ejini uye kunotevera kuburitswa kwemagasi ekupedza. Zvinhu zvakakosha zvehurongwa mavharuvhu, ayo, pakati pezvimwe zvinhu, anofanirwa kuve nechokwadi chekusimba kwekamuri yekupisa. Vanosangana nemitoro inorema, saka basa ravo rinoenderana nezvinodiwa zvakakosha.

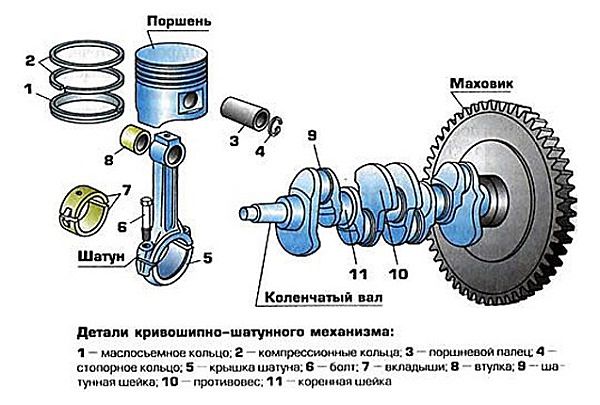

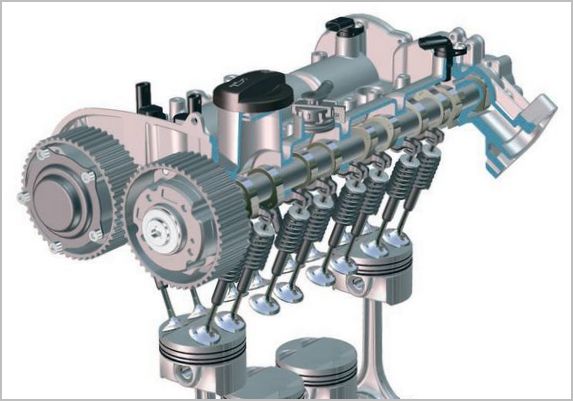

Zvinhu zvikuru zvemagetsi evhavha

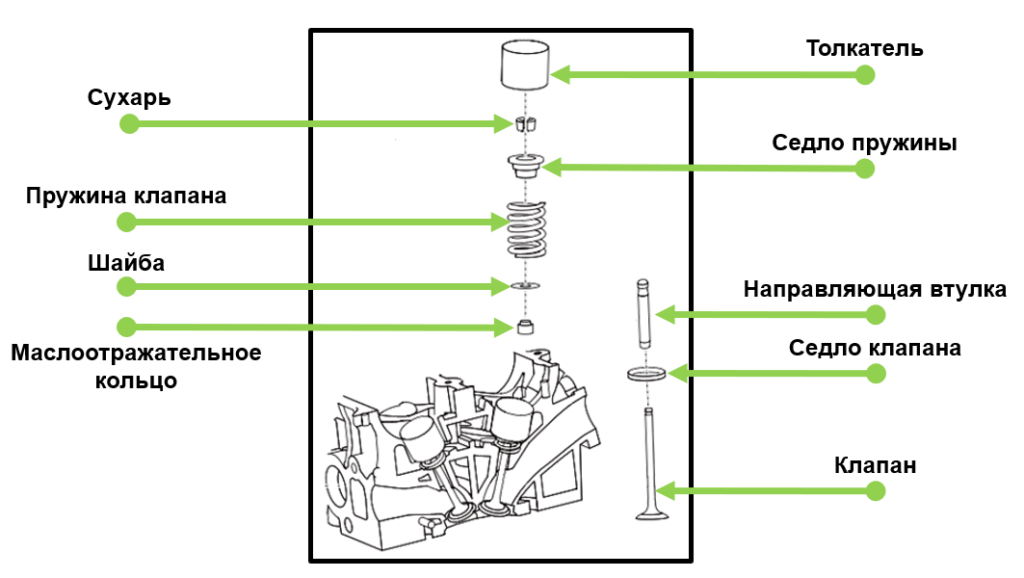

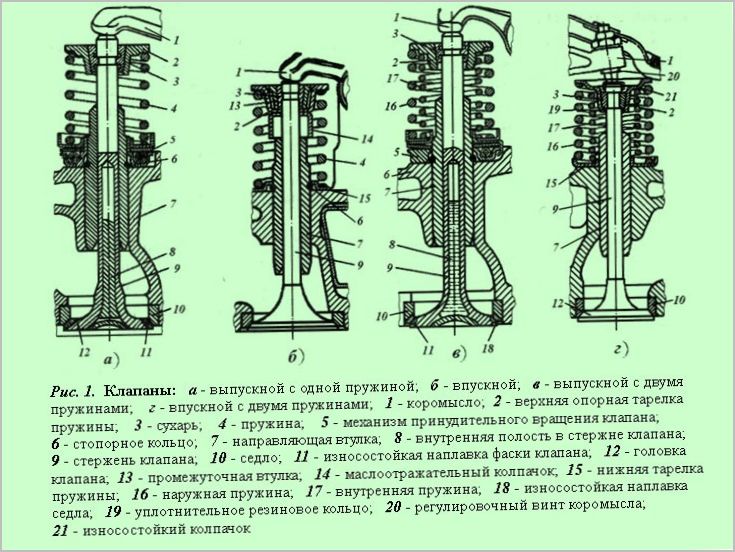

Injini inoda kanenge mavharuvhu maviri pahumburumbira, inopinza uye yekupopota, kuti ishande nemazvo. Ivhavha pachayo ine hunde uye musoro muchimiro chendiro. Chigaro ndipo panosangana musoro wevharuvhu nemusoro wecylinder. Mavharuvhu ekupinza ane dhayamita yemusoro yakakura kupfuura mavharuvhu emhepo. Izvi zvinovimbisa kuzadza zviri nani kwekamuri yekupisa nemusanganiswa wemhepo-mafuta.

Zvinhu zvikuru zvemeshini:

- kupinza uye kupera mavharuvhu - akagadzirirwa kupinda mumhepo-mafuta musanganiswa uye kubudisa magasi kubva mukamuri rinopisa;

- kutungamira bushings - chengetedza iyo chaiyo nzira yekufamba kwemavharuvhu;

- chitubu - inodzorera valve panzvimbo yayo yepakutanga;

- chigaro chevhavha - nzvimbo yekubatana kweplate ine musoro we cylinder;

- crackers - kushanda sechitsigiro chechitubu uye kugadzirisa iyo yose chimiro);

- valve stem seals kana mafuta slinger zvindori - inodzivirira mafuta kupinda muhumburumbira;

- pusher - inotumira kudzvanywa kubva kucamshaft cam.

Iwo makamera ari pa camshaft anodzvanya pamavharuvhu, ayo ari muchirimo-akaremerwa kuti adzokere kunzvimbo yawo yekutanga. Chitubu chakabatanidzwa kune tsvimbo ine crackers uye ndiro yechitubu. Kuti uderedze kudengenyeka kweresonant, kwete imwe chete, asi zvitubu zviviri zvine mhepo yakasiyana-siyana zvinogona kuiswa padanda.

Sleeve yekutungamira ichidimbu checylindrical. Inoderedza kukakavara uye inovimbisa kushanda kwakanaka uye kwakaringana kwetsvimbo. Panguva yekushanda, zvikamu izvi zvakare pasi pekunetseka uye tembiricha. Nokudaro, ma alloys asingasviki uye anodzivirira kupisa anoshandiswa pakugadzira kwavo. Exhaust uye intake valve bushings zvakasiyana zvishoma kubva kune mumwe nemumwe nekuda kwekusiyana kwemutoro.

Mashandiro anoita vharafu

Mavharuvhu anogara achiratidzwa kune tembiricha yakakwira uye kumanikidza. Izvi zvinoda kunyatsotariswa kwekugadzira uye zvinhu zvezvikamu izvi. Izvi zvinonyanya kuitika kune boka rekupedza simba, sezvo magasi anopisa anobuda mairi. Ivharuvhu yekuburitsa ndiro painjini dzepeturu inogona kudziyisa kusvika 800˚C - 900˚C, uye painjini dzedhiziri 500˚C - 700C. Mutoro uri paplate yevhavha inopinza kakati wandei zvishoma, asi unosvika 300˚С, iyo yakawandawo.

Naizvozvo, kupisa-resistant metal alloys ane alloying additives anoshandiswa mukugadzira kwavo. Mukuwedzera, mavharuvhu ekupedza anowanzo ane sodium-yakazadzwa hollow stem. Izvi zvinodiwa kuti zviri nani thermoregulation uye kutonhora kweplate. Iyo sodium iri mukati metsvimbo inonyunguduka, inoyerera, uye inotora kumwe kupisa kubva mundiro uye inoendesa kune tsvimbo. Nenzira iyi, kupisa kwechikamu kunogona kudziviswa.

Panguva yekushanda, carbon deposits inogona kuumba pachigaro. Kuti izvi zvisaitike, magadzirirwo anoshandiswa kutenderedza valve. Chigaro chine simba rakakwirira simbi alloy mhete inotsikirirwa yakananga muhumburumbira mumusoro kuti ibatane.

Mukuwedzera, nokuda kwekushanda kwakarurama kwechigadziro, zvakakosha kutarisa iyo yakagadziriswa gap yekushisa. Kupisa kwakanyanya kunoita kuti zvikamu zviwedzere, izvo zvinogona kuita kuti valve isashande. Mukaha uripo pakati pemakamera ecamshaft nemapusher unogadziriswa nekusarudza masheshi esimbi akasarudzika ehumwe ukobvu kana mapusher pachawo (magirazi). Kana injini ichishandisa hydraulic lifters, ipapo gap rinogadziriswa otomatiki.

Kusununguka kukuru kunodzivirira vharuvhu kuti isavhure zvizere uye saka macylinders anozadza nemusanganiswa mutsva zvisingaite. Chikamu chiduku (kana kushayikwa kwayo) hachizobvumiri mavharuvhu kuti avhare zvachose, izvo zvinotungamirira pakupisa kwevhavha uye kuderera kwekumanikidza injini.

Kurongwa nehuwandu hwemavharuvhu

Iyo yekare vhezheni yechina-stroke injini inoda mavharuvhu maviri chete pacylinder kuti ishande. Asi injini dzemazuva ano dzinotarisana nezvido zvakawanda maererano nemasimba, kushandiswa kwemafuta uye kuremekedza zvakatipoteredza, saka izvi hazvisisina kukwana kwavari. Sezvo mavharuvhu akawanda, iyo inonyanya kushanda ichava yekuzadza silinda nechaji nyowani. Panguva dzakasiyana, zvirongwa zvinotevera zvakaedzwa painjini:

- matatu-vhavha (inlet - 2, kubuda - 1);

- mana-vhavha (inlet - 2, kupera - 2);

- shanu-vharuvhu (inlet - 3, kupera - 2).

Kuzadza zviri nani uye kucheneswa kwemasilinda kunowanikwa nemamwe mavharuvhu pa cylinder. Asi izvi zvinokanganisa dhizaini yeinjini.

Nhasi, injini dzinonyanya kufarirwa dzine mavharuvhu mana pahumburumbira. Yekutanga yeinjini idzi yakaonekwa muna 4 paPeugeot Gran Prix. Panguva iyoyo, mhinduro iyi haina kushandiswa zvakanyanya, asi kubva muna 1912 motokari dzakagadzirwa nemhando dzakawanda dzevhavha dzakatanga kugadzirwa.

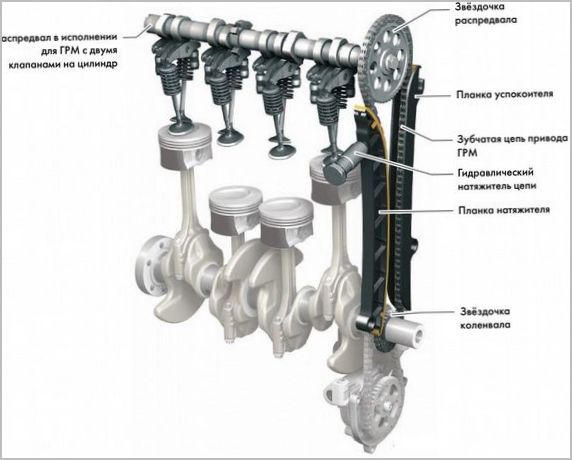

Dhiraivha dhizaini

Iyo camshaft uye nguva yekutyaira ndiyo ine basa rekuita kwakaringana uye nenguva yekushanda kweiyo valve mechanism. Dhizaini uye nhamba yecamshafts yemhando yega yega injini inosarudzwa mumwe nemumwe. Chikamu ishaft pane makamera echimwe chimiro. Pavanotendeuka, vanoisa kumanikidza pamapushrods, hydraulic lifters kana rocker maoko uye vanovhura mavharuvhu. Mhando yedunhu inoenderana neinjini chaiyo.

Iyo camshaft inowanikwa zvakananga muhumburumbira musoro. Kutyaira kwairi kunobva ku crankshaft. Inogona kuva cheni, bhandi kana giya. Inonyanya kuvimbika iketani, asi inoda zvishandiso zvekubatsira. Somuenzaniso, cheni vibration damper (damper) uye tensioner. Iko kumhanya kwekutenderera kwecamshaft ihafu yekumhanya kwekutenderera kwe crankshaft. Izvi zvinovimbisa basa ravo rakarongeka.

Nhamba ye camshafts inobva pane nhamba yevhavha. Pane zvirongwa zviviri zvikuru:

- SOHC - ine shaft imwe;

- DOHC - matanda maviri.

Mavharuvhu maviri chete anokwana kune imwe camshaft. Inotenderera uye inovhura mavharuvhu ekupinza uye ekupera simba. Injini dzinowanzozivikanwa ina-vharuvhu dzine maviri camshafts. Imwe inovimbisa kushanda kwemavharuvhu ekutora, uye imwe inovimbisa mavharuvhu ekupedza. V-mhando injini dzine camshafts ina. Vaviri kurutivi rumwe norumwe.

Iwo macamshaft makamera haasundire hunde yevharuvhu zvakananga. Kune marudzi akawanda e "intermediaries":

- roller levers (rocker arm);

- mechanical pushers (magirazi);

- hydraulic pushers.

Roller levers ndiyo yakasarudzika gadziriro. Iwo anonzi mawoko e rocker anozununguka pama plug-in axles oisa pressure pa hydraulic pusher. Kuti uderedze kupokana, roller inopiwa pane lever inobata zvakananga kamera.

Mune imwe chirongwa, hydraulic pushers (gap compensators) inoshandiswa, iyo inowanikwa zvakananga padanda. Hydraulic compensator inogadzirisa yega gap yekupisa uye inopa kushanda kwakapfava uye kwakanyarara kwechigadzirwa. Ichi chidiki chidiki chine silinda ine piston uye chitubu, mafuta ndima uye cheki valve. Iyo hydraulic pusher inofambiswa nemafuta anopihwa kubva kune injini lubrication system.

Mechanical pushers (magirazi) akavharwa bushings kune rumwe rutivi. Iwo akaiswa muhumburumbira musoro imba uye zvakananga kutamisa simba kune tsinga yevharuvhu. Kukanganisa kwayo kukuru ndiko kudiwa kwekugadzirisa nguva nenguva mapeji uye kugogodza paunenge uchishanda nejini inotonhora.

Noise kubasa

Iyo huru yevharuvhu kusashanda kugogodza pane inotonhora kana inopisa injini. Kugogodza painjini inotonhora inonyangarika mushure mekunge tembiricha yakwira. Pavanopisa uye vachiwedzera, gaka rekupisa rinovhara. Mukuwedzera, iyo viscosity yemafuta, iyo isingayerere muhuwandu hwakakodzera mukati meiyo hydraulic lifters, inogona kunge iri chikonzero. Kusvibiswa kwematanho emafuta emutsinhanisi anogonawo kuva chikonzero chechimiro chekubata.

Mavharuvhu anogona kugogodza painjini inopisa nekuda kwekudzikira kweoiri kudzvinyirirwa murubrication system, yakasviba mafuta sefa, kana isiriyo yekupisa kupisa. Izvo zvinodiwawo kufunga nezvekupfeka kwechisikigo kwezvikamu. Kukanganisa kunogona kunge kuri mumagetsi evhavha pachayo (kupfeka kwechirimo, kutungamira sleeve, hydraulic tappets, nezvimwewo).

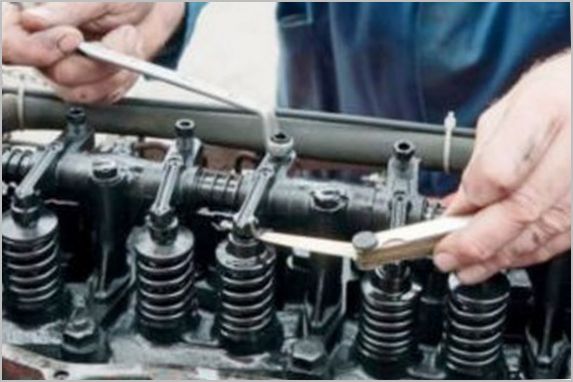

Clearance kugadzirisa

Kugadziriswa kunoitwa chete pane inotonhora injini. Ikozvino kupisa gap kunotarirwa neakakosha flat simbi probes ehukobvu hwakasiyana. Kuti uchinje gap pamaoko e rocker pane yakakosha kugadzirisa screw inotendeuka. Mune masisitimu ane pusher kana shims, kugadzirisa kunoitwa nekusarudza zvikamu zvehukobvu hunodiwa.

Funga nezve nhanho-ne-nhanho maitiro ekugadzirisa mavharuvhu einjini ane pushers (magirazi) kana washers:

- Bvisa chivharo chevhavha yeinjini.

- Shandura crankshaft kuitira kuti piston yecylinder yekutanga iri pamusoro pekufa pakati. Kana zvakaoma kuita izvi nemaki, unogona kusunungura spark plug woisa screwdriver mutsime. Kukwirira kwayo kukwira kumusoro kuchave kwakafa pakati.

- Uchishandisa seti yezviyero zvekunzwa, pima kubvisirwa kwevharuvhu pasi pemakamera asiri kudzvanya pamatepi. Iyo probe inofanirwa kunge iine yakasimba, asi kwete yakasununguka kutamba. Rekodha nhamba yevharuvhu uye kukosha kwekubvisa.

- Tenderedza crankshaft imwe shanduko (360 °) kuunza 4th silinda piston kuTDC. Edza kujekesa pasi pemamwe mavharuvhu. Nyora pasi data.

- Tarisa kuti ndeapi mavharuvhu asina kushivirira. Kana paine, sarudza ma pushers ehukobvu hunodiwa, bvisa camshafts uye isa magirazi matsva. Izvi zvinopedzisa maitiro.

Inokurudzirwa kutarisa mapeji ega ega 50-80 zviuru zvemakiromita. Standard clearance values inogona kuwanikwa mubhuku rekugadzirisa mota.

Ndokumbira utarise kuti mavharuvhu ekutora uye ekupedza simba anogona kumbosiyana.

Iyo yakagadziridzwa zvakanaka uye yakarongedzwa gasi yekugovera nzira inovimbisa yakatsetseka uye kunyangwe kushanda kweinjini yekupisa yemukati. Izvi zvichavawo nemigumisiro yakanaka pane injini zviwanikwa uye mutyairi nyaradzo.