|

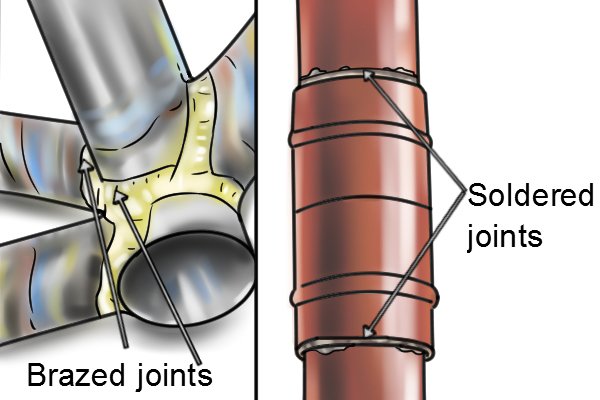

| Soldering inzira yekubatanidza mapaipi maviri esimbi pamwe chete nechinhu chinonzi solder. |

|

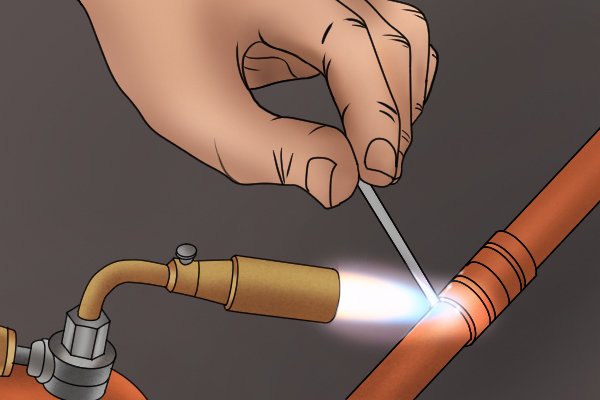

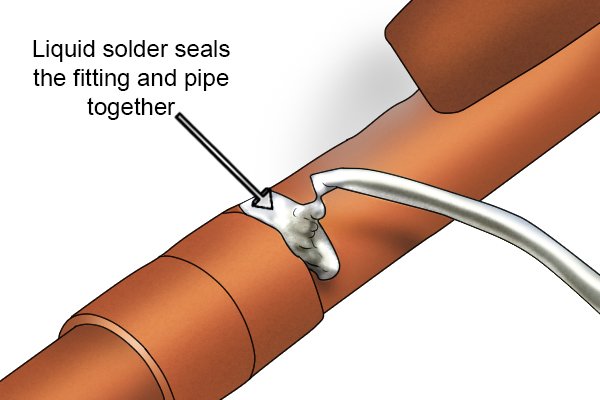

| Inoshanda nekupisa zvikamu zviviri sezvazvinenge zvakabatanidzwa pamwe chete uye zvino kuwedzera solder inopfava sezvainopisa. Iyo solder ichanyunguduka uye mukuita ichiyerera ichipinda mukaha pakati pemapombi maviri, ichigadzira mubatanidzwa wemhepo. |

| Soldering inogona kureva zvese zvakapfava solder uye zvakaoma soldering. Misiyano yezviviri izvi iri mumhando ye solder inoshandiswa kubatanidza zvinhu uye tembiricha inodiwa kuzvinyungudutsa. |

| Soldering and soldering rods zvimedu zvesimbi alloys ayo anonyunguduka akadzikira pane aya emarata achabatanidzwa. Brazing kana kuti brazing alloys anogadzirwa kubva kune alloys ane sirivheri, mhangura, kana nickel ane painonyungudika inopfuura 450 degrees Celsius (842 degrees Fahrenheit). |

| Kune rimwe divi, waya inotengeswa inogadzirwa kubva musanganiswa we zinc, mhangura, lead, bismuth uye antimony kana palladium. Masimbi aya ane kunyungudika kwe180 kusvika 190 degrees Celsius (356 kusvika 374 degrees Fahrenheit). |

| Lead-isina solder inofanira kushandiswa pakugadzira pombi basa. Lead-isina inoreva solder ine lead yemukati isingasviki 0.2%, isina lead-isina zvachose. Izvi zvakakwana kudzivirira mutobvu kupinda mumvura. |