Chishandiso uye musimboti wekushanda kwemultiport mafuta jekiseni MPI

Zviri mukati

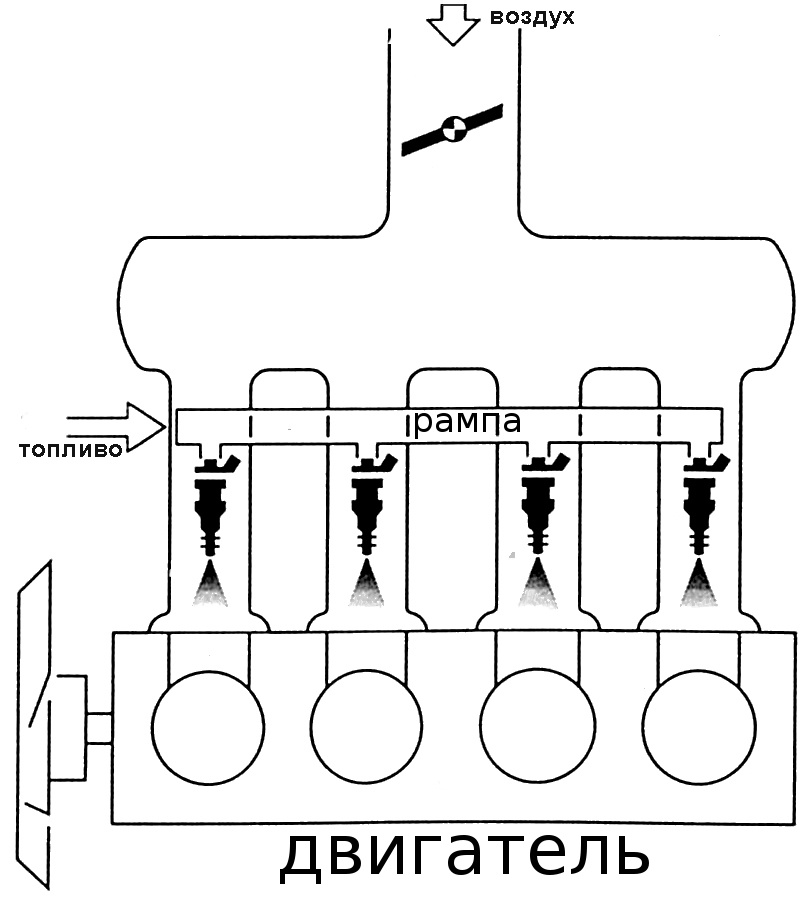

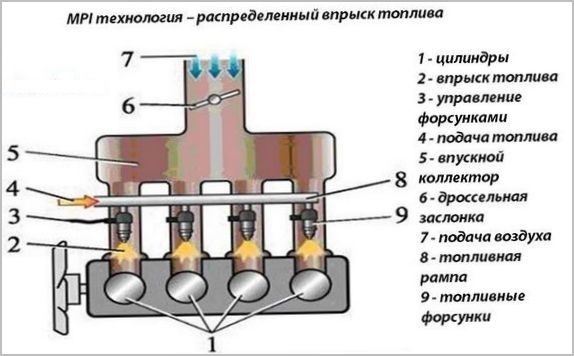

Majekiseni emafuta anodzvanyirirwa akabuda kubva kumidziyo yakapfava kuenda kumagetsi anodzorwa masisitimu anodhiza mafuta ega ega enjini. Chidimburidzo cheMPI (Multi Point Injection) chinoshandiswa kuratidza musimboti wekugovera peturu nemajekiseni emagetsi kune yakawanda yekudyara, padyo sezvinobvira kunze kwevharuvhu yekupinda. Parizvino, iyi ndiyo nzira yakajairika uye yakakura yekuronga magetsi emagetsi epeturu.

Izvo zvinosanganisirwa muhurongwa

Chinangwa chikuru chekuvaka uku chaive chakarurama dosing ye cyclic mafuta ekupa, ndiko kuti, kuverenga uye kucheka-kubviswa kwehuwandu hunodiwa hwepeturu, zvichienderana nemhepo yakawanda inopihwa kune masilinda uye mamwe akakosha ezvino injini paramita. Izvi zvinotsigirwa nekuvapo kwezvikamu zvikuru:

- pombi yemafuta inowanzowanikwa mugasi tangi;

- pressure regulator uye mutsara wemafuta, inogona kuva imwe chete kana kaviri, ine mafuta ekudzosa dhizaini;

- rampu ine majekiseni (majekiseni) anodzorwa nemagetsi emagetsi;

- injini yekudzora unit (ECU), kutaura zvazviri, imicrocomputer ine advanced peripherals, isingaperi, inonyorwazve uye isina kujairika yekuwana memory;

- akawanda sensors anotarisa injini inoshanda modhi, chinzvimbo chekutonga uye mamwe masisitimu emotokari;

- actuators uye mavharuvhu;

- software uye hardware yakaoma yekudzima moto, yakanyatsobatanidzwa muECM.

- dzimwe nzira dzekuderedza chepfu.

Midziyo yacho inogoverwa mukati memukati memotokari kubva patrunk kusvika kune injini, node dzakabatanidzwa nemagetsi wiring, mabhasi data data, mafuta, mhepo uye vacuum mitsara.

Kushanda kwemayuniti ega ega uye zvishandiso zvakazara

peturu inopihwa kubva mutangi rakadzvanywa nepombi yemagetsi iri ipapo. Iyo mota yemagetsi uye chikamu chepombi chinoshanda munharaunda yepeturu, ivo zvakare vakatonhodzwa uye nekuzorwa nayo. Kuchengetedzwa kwemoto kunovimbiswa nekushaikwa kweokisijeni inodiwa pakubatidza; musanganiswa nemweya wakafumiswa nepeturu haubatiswe nemoto wemagetsi.

Mushure mekusefa kwematanho maviri, peturu inopinda munjanji yemafuta. Kudzvinyirirwa mairi kunochengetedzwa kugadzikana nerubatsiro rwemugadziri wakavakwa mupombi kana njanji. Yakawandisa inodonhedzwa zvakare mutangi.

Panguva yakakodzera, magetsi emagetsi emajekiseni, akaiswa pakati perampu uye manifold ekutora, anogamuchira chiratidzo chemagetsi kubva kune vatyairi veECM kuti vavhure. Iyo mafuta yakamanikidzwa inoiswa muvharuvhu yekudya, panguva imwe chete ichipfapfaidza uye ichibuda. Sezvo kudonhedzwa kwemhepo kune jekiseni kunochengetwa kwakagadzikana, chiyero chepeturu chinopiwa chinotaridzirwa nenguva yekuvhura yevhavha yejekiseni. Shanduko yevacuum muunganidzi inotariswa nehurongwa hwekutonga.

Iyo nozzle yekuvhura nguva ndeye yakaverengerwa kukosha yakaverengerwa pahwaro hwe data yakagamuchirwa kubva kuma sensors:

- kuyerera kwemhepo yakawanda kana kuwanda kwakazara kudzvinyirira;

- kutora gasi tembiricha;

- throttle kuvhura degree;

- kuvapo kwezviratidzo zvekupisa kwe detonation;

- injini tembiricha;

- kuwanda kwekutenderera uye zvikamu zvechinzvimbo che crankshaft uye camshafts;

- kuvapo kweokisijeni mumagasi emhepo isati yasvika uye mushure mekushandura catalytic.

Uye zvakare, iyo ECM inogamuchira ruzivo kubva kune mamwe masisitimu emotokari kuburikidza nebhasi data, ichipa injini mhinduro mumamiriro akasiyana. Iyo block chirongwa inoramba ichichengetedza torque yemasvomhu modhi yeinjini. Zvese zvarinongogara zvakanyorwa mumultidimensional mode mepu.

Kuwedzera kune yakananga jekiseni kutonga, iyo sisitimu inopa kushanda kwemamwe maturusi, coils uye spark plugs, tank ventilation, thermal kudzikamisa uye mamwe mabasa mazhinji. Iyo ECM ine Hardware uye software yekuzviongorora wega uye kupa mutyairi ruzivo nezve kuitika kwekukanganisa uye malfunctions.

Parizvino, jekiseni rega rega rega rega rega rega rinoshandiswa. Munguva yakapfuura, majekiseni akashanda panguva imwe chete kana ari maviri, asi izvi hazvina kugadzirisa maitiro mujini. Mushure mekuunzwa kwecamshaft chinzvimbo sensors, silinda yega yega yakagamuchira yakaparadzana kutonga uye kunyange diagnostics.

Hunhu hunhu, zvakanakira uye nekuipira

Iwe unogona kusiyanisa MPI kubva kune mamwe majekiseni masisitimu nekuvapo kwemanozzles ega ane rampu yakajairwa inotungamirwa mune akawanda. Jekiseni repapini rimwechete raive nejekiseni rimwechete rakatora nzvimbo yecarburetor uye rakafanana pakuonekwa kwaro. Jekiseni rakananga mumakamuri ekupisa rine mhuno dzakafanana nemidziyo yemafuta edhiziri ine pombi yekumanikidza yakakwira yakaiswa mumusoro webhuroko. Kunyangwe dzimwe nguva, kutsiva kukanganisa kwejekiseni rakananga, rinopihwa parallel inoshanda rampu yekupa chikamu chemafuta kune akawanda.

Iko kudikanwa kwekuronga kupisa kwakanyatsoita mumasilinda kwakatungamira mukuvandudzwa kwemidziyo yeMPI. Iyo mafuta inopinda mumusanganiswa sepedyo sezvinobvira kukamuri yekupisa, inobudirira sprays uye inoputika. Izvi zvinokutendera kuti ushande pane yakanyanya kuonda musanganiswa, kuve nechokwadi chekushanda.

Chaiyo chekombuta chekudya chekudzora chinoita kuti zvikwanise kusangana neanogara achiwedzera huturu zviyero. Panguva imwecheteyo, mitengo yehardware yakadzikira, michina ine MPI yakachipa kugadzira pane nemajekiseni akananga. Yakakwirira uye yakasimba, uye kugadzirisa kunodhura zvishoma. Zvese izvi zvinotsanangura kuwanda kweMPI mumotokari dzemazuvano, kunyanya makirasi ebhajeti.