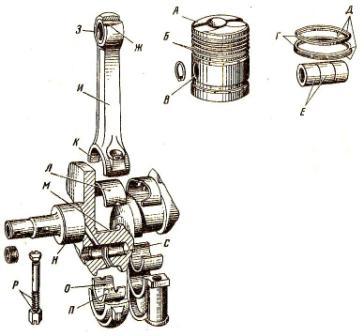

Kugadziriswa kwekubatanidza tsvimbo uye piston kit

Kukanganisa kukuru kwezvikamu zvetambo yekubatanidza uye piston kit inoratidzwa muMufananidzo 64.

Mupunga. 64. Zvikanganiso zvinokwanisika muzvikamu zvekubatanidza tsvimbo uye piston kit.

A) - dhipoziti ye soot, coke, tara;

B) - groove kupfeka;

B) - kupfeka kwemakomba kune zvigunwe mupiston;

D) - kupfeka kwekunze kwekunze kwemhete;

D) - kupfeka zvindori pakureba;

E) - kupfeka kweminwe kunze;

D) - kupfeka kwekunze kwekunze kwetsvimbo yekubatanidza;

H) - kupfeka kwebhushi mukati mekubatanidza tsvimbo;

I) - Kupeta uye kuputika kwetambo yekubatanidza;

K) - kupfeka kwemukati kwemusoro wezasi wetsvimbo yekubatanidza;

L) - pfeka kunze kwechigadziko;

M) - kupfeka kwebhuku rekubatanidza tsvimbo;

H) - Kupfeka kukuru kwemutsipa;

O) - kupfeka kwemukati wemukati wemucheka;

P) - Kuparara kweiyo antenna inokwira inopinza;

P) - Kuputika uye kuparadzwa kwetambo dzekubatanidza tsvimbo mabhoti;

C) - Deposition yezvigadzirwa zvekupfeka.

Iyo piston yepiston inodzoreredzwa nekuwedzera kunotonhora (plastic deformation) inoteverwa nekupisa kurapwa, hydrothermal kuwedzera pamwe panguva imwe chete yekupisa kurapwa, electroplating (chromium plating, hard iron) nzira. Mushure mekudzoreredzwa, mapini episton anogadziriswa pamichina yekukuya isina pakati uye yakakwenenzverwa kusvika kune yakajairika saizi, nepo kushata kwepamusoro kunosvika kuRa = 0,16-0,32 microns.

Nekugovera kwehydrothermal, HDTV inopisa chigunwe muinductor kusvika kune tembiricha ye790-830 madhigirii Celsius, yozoitonhodza nemvura inoyerera, ichipfuura nepamukati mayo. Muchiitiko ichi, munwe unoomesa, kureba kwayo uye kunze kwedhayamita kunowedzera kubva 0,08 kusvika 0,27 mm. Zvigunwe zvakarebesa zvinogadzikwa kubva kumigumo, ipapo chamfers inobviswa kubva kunze uye mukati.

Bushings yemusoro wepamusoro wetsvimbo yekubatanidza. Vanodzorerwa nenzira dzinotevera: thermal diffusion zinc plating nekugadzirisa kunotevera; inoisa mudanda rekubatanidza; kudzvinyirirwa kunoteverwa nekugadzirwa kwekunze kwesimbi tepi ne electrocontact welding (ukobvu hwematepi kubva pasi-carbon steels ndeye 0,4-0,6 mm).

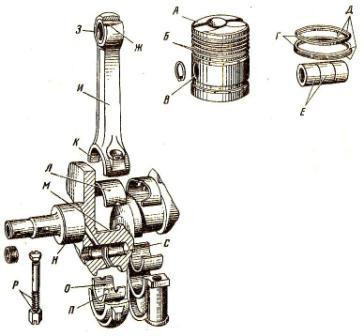

Kubatanidza tsvimbo. Kana nzvimbo iri pasi pegwenzi yakapfekwa, tsvimbo yekubatanidza inodonhedzwa kune imwe yehukuru hwekugadzirisa ine nguva ye 0,5 mm, chamfering kumagumo 1,5 mm x 45 degrees. Nekuda kufinha, URB-VP diamond yekuchera muchina inoshandiswa, kugadzirisa tsvimbo yekubatanidza [Mufananidzo makumi matanhatu neshanu].

Mupunga. 65. Kusunga tsvimbo yekubatanidza kumushini nekuchera bushing yemusoro wepamusoro.

1) - Kugadzirisa;

2) - Zvifambiso zvekutakura;

3) - Gumbo rekufambisa kwemotokari;

4) - kuvhara screw yengoro;

5) - Tsigiro;

6) - nhare;

7) - Tsigiro;

- Kubatanidza tsvimbo.

Muchina uyu unogona kuboora maburi ane dhayamita ye28-100 mm nekumhanya kwe600-975 min-1 uye chikafu che0,04 mm/rev.

Nharaunda pakati pemasanhu epamusoro nepamusoro misoro inowanikwa nekuisa template pakati pekumira kwebhuraketi (5) uye chingoro chinotakurika. Kururamisa kwekuiswa kwegomba rekubatanidza tsvimbo mundege yakatwasuka inotariswa nemucheki uye inogadziriswa nebhureki (7).

Yakapfekwa mukati memisoro yezasi uye yepamusoro yezvisungo zvekubatanidza muzvitoro zvekugadzirisa zvinowedzerwa ne electroplating, kudhirowa nekukuya kana kupuruzira kune yakajairika saizi.

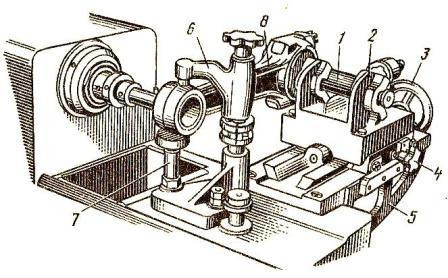

Kuti uone kutsauka kubva kuparallelism (kukotama) mundege dzakasimukira uye dzakachinjika (torsion) dzemasanhu emusoro wepamusoro hukama kune yakaderera pane carburetor injini, iyo yekubatanidza tsvimbo yekubatanidza ine chivharo inotariswa pane yakakosha mudziyo [ENG. 66], uye kune vamwe vese, fonera 70-8735-1025.

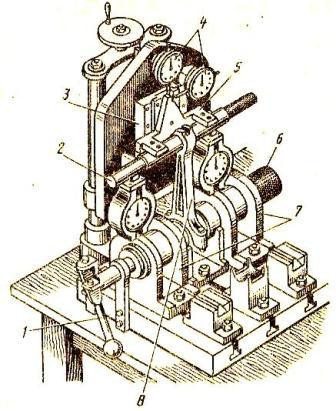

Mupunga. 66. Chigadzirwa chekugadzirisa kwekubatanidza tsvimbo dzeinjini dzemotokari.

1) - mubato wekubvisa roller;

2) - duku mandrel;

3) - sliding vatungamiri;

4) - zviratidzo;

5) - rocker;

6) - mandrel hombe;

7) - Sherufu;

- Kubatanidza tsvimbo.

Kutsauka kubva kuparallelism (kukotama) kwemasanhu emisoro mikuru yetsvimbo yekubatanidza kunobvumidzwa kune injini dzedhiziri:

D-50 - 0,18mm;

D-240 - 0,05mm;

SMD-17, SMD-18 - 0,15mm;

SMD-60, A-01, A-41 - 0,07mm;

YaMZ-238NB, YaMZ-240B - 0,08mm.

Kufamba kunobvumidzwa:

D-50 - 0,3mm;

D-240 uye YaMZ-240NB - 0,08mm;

SMD-17, SMD-18 - 0,25mm;

SMD-60 - 0,07mm;

A-01, A-41 - 0,11mm;

YaMZ-238NB - 0,1mm.

Kune injini dzemotokari, kutsauka kubva pakufanana kweshafts mundege dzose hazvibvumirwi kupfuura 0,05 mm pamusoro pehurefu hwe100 mm. Kuti abvise kukanganisa uku, zvinotenderwa kugadzirisa matanda ekubatanidza chete mushure mekupisa tsvimbo yavo nepamusoro-frequency current kana gasi rinopisa moto pakupisa kwe450-600 degrees Celsius, kureva, nekugadzirisa kupisa.

Pistons Kudzoreredzwa kwepistons eSMD dizeli injini zvinogoneka neplasma-arc pamusoro. Kuti uite izvi, piston inocheneswa mumunyu wakanyungudutswa pakupisa kwe 375-400 degrees Celsius kwemaminitsi gumi, yakashambidzwa, inobatwa ne10% nitric acid uye yakashambidzwa zvakare nemvura inopisa kubvisa varnish uye carbon deposits mu grooves. Mupiston, groove yepamusoro uye musoro zvakakandwa neSVAMG waya uye yakagadzirwa.

Packing, assembly. Seti yekubatanidza tsvimbo nemakapisi, bots uye nzungu zvinosarudzwa nehuremu zvinoenderana netafura 39.

Tafura 39

| Injini gadzira | Huremu musiyano, g | ||

| matanda ekubatanidza | pisitoni | kubatanidza tsvimbo ne piston assembly | |

| A-01M, A-41 | 17 | makumi maviri | 40 |

| YaMZ-240B, YaMZ-238NB | 17 | 10 | makumi matatu |

| SMD-14, SMD-62 nevamwe | 10 | 7 | 22 |

| D-240, D-50 | makumi maviri | 10 | makumi matatu |

| D-37M | 10 | 10 | 25 |

| GAZ-53, ZIL-130 | 8 | 5 | gumi nematanhatu |

Pane vamwe vavo, kuwanda kunoratidzwa pamusoro pekunze kwemusoro wezasi, pachivharo chakafanana negomba rekubatanidza tsvimbo yebhaudhi. Kana zvakakosha kuenzanisa kuwanda, zvakakosha kuisa simbi yetambo yekubatanidza pamwe chete nemutsara wekuparadzaniswa kwezvisimbiso kusvika pakadzika 1 mm.

Misiyano muhuwandu hwezvikamu mumusangano weinjini panguva yekushanda kwayo inotungamirira pakubuda kwemasimba asina kukwana inertia, izvo zvinokonzera kuzununguka uye kukurumidza kupfeka kwezvikamu.

Nehuremu hwakafanana hwetambo yekubatanidza, kugoverwa kwezvinhu pamwe chete nekureba kunofanira kuva kwakadaro zvokuti misimboti yemisoro yakadzika uye yepamusoro mumucheka wekubatanidza tsvimbo yakaenzana (musiyano haufaniri kudarika ± 3 gramu).

Pistons inosarudzwawo nehukuru uye uremu. Huremu hwepiston hunoratidzwa pasi payo. Mapistoni ane maoko anopedzwa zvichienderana nemukaha uri pakati pepiston (pamwe siketi) uye sleeve, ichigadzira mapoka nemavara echiRussian alphabet (B, C, M, nezvimwewo), anobviswa pazasi pepiston uye pabendekete remaoko.

Mapini episton anosarudzwa zvichienderana nehukuru hweboka remakomba mumisoro yepiston uye akaiswa mapendi kana nhamba 0,1, 0,2, nezvimwe.

Bushings maererano nehupamhi hwekunze inosarudzwa maererano nehupamhi hwemusoro wepamusoro wetsvimbo yekubatanidza, uye maererano nehupamhi hwemukati - maererano nehupamhi hwepini, uchifunga nezvekubvumirwa kwekugadzira.

Iwo maraini anofanira kuenderana nedhayamita ye crankshaft journals.

Zvindori zvepiston zvinosarudzwa zvinoenderana nehukuru hwema liner uye kubvumidzwa mupiston groove, iyo inotenderwa yekutanga mhete ye dizeli injini yeYaMZ, A-41 uye SMD-60 marudzi e 0,35 mm (kune mamwe - 0,27 mm). Pachikamu chechipiri uye chechitatu chekumanikidza, gap iri 0,30 mm uye 0,20 mm, zvichiteerana.

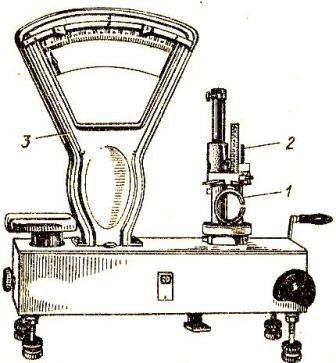

Iyo elasticity yezvindori inotariswa nekuisa pamwe chete munzvimbo yakachinjika pachikuva chechiyero chakakosha MIP-10-1 [Fig. 67]. Iyo mhete inotakurwa neyakajairika hinge clearance. Simba rinoratidzwa pane dial yekero rinofanira kusangana nezvinodiwa zvehunyanzvi.

Mupunga. 67. Kutarisa elasticity yezvindori zvepiston mumudziyo.

1) - Mhete;

2) - mudziyo;

3) - Pondo.

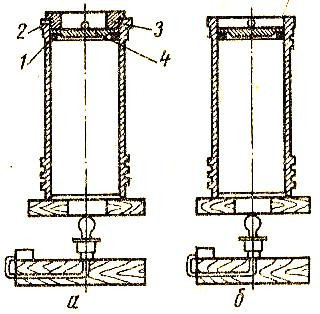

Kuti utarise gaka riri mu gasket, zvindori zvepiston zvinoiswa muhumburumbira zvakanyatsonaka mundege perpendicular kune axis uye yakatariswa neanonzwa gauge. Hunhu hwekukodzera kwemhete kumadziro ecylinder muchiedza hunotariswawo [Fig. 68].

Mupunga. 68. Kutarisa kubviswa kwepiston zvindori.

a) - Kuiswa kwemhete,

b) - cheki;

1) - Mhete;

2) - Sleeve (silinda yekutsigira);

3) - Mhete yekutungamira;

4) - Murayiridzo.

Mukana uri pajoko rezvindori zvitsva zveinjini dzedizeli inofanira kuva 0,6 ± 0,15 mm, inobvumirwa pasina kugadziriswa - kusvika 2 mm; nokuti itsva carburetor injini zvindori - 0,3-0,7 mm.

Iyo radial play (backlash) pakati pemhete necylinder yeinjini dzedhiziri haifanire kudarika 0,02 mm munzvimbo dzinopfuura mbiri pamwe nemaarcs e30 madhigirii uye kwete pedyo kupfuura 30 mm kubva pakiyi. Kune zvindori uye conical zvindori, gaka rinotenderwa kwete kupfuura 0,02 mm, yemafuta scraper zvindori - 0,03 mm chero kupi, asi kwete pedyo kupfuura 5 mm kubva kukiya. Kutamba muzvindori zve carburetor injini hazvibvumirwi.

Vanotarisawo kureba kwemhete uye kukanganisa kwemagumo ekupedzisira, izvo zvisingafaniri kudarika 0,05 mm nokuda kwemadhayamita kusvika 120 mm uye 0,07 mm yezvindori zvehupamhi hukuru.

kusangana uye kutonga. Iko kuungana kwetambo yekubatanidza uye piston kit kunotanga nekutsikirira mabhushi kumusoro weiyo tsvimbo yekubatanidza nekupindirana kwakaenzana kwe 0,03-0,12 mm yeinjini dzedhiziri dzemhando dzakasiyana, 0,14 mm yeinjini carburetor. Tsvimbo yekubatanidza inoiswa pamushini wekuchera madhaimondi weURB-VP nenzira imwechete seyakaratidzwa muMufananidzo 65, ipapo bushing inodhiriwa nemvumo:

yakakungurutswa 0,04-0,06mm,

pakusandura ne 0,08-0,15 mm kana kudzorerazve ne 0,05-0,08 mm maererano nedhayamita yakajairika yepini yepiston.

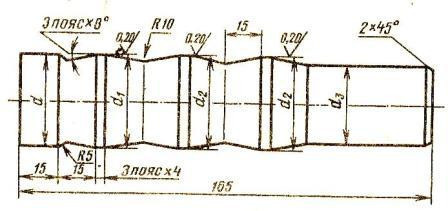

Mabhushi anokungurutswa nekupuruzira kutenderedzwa pamushini wekuchera wakatwasuka, wakafinhwa pasi pemuchina unofambiswa nemichina ine inoenderera mberi mandrel feed [Fig. 69], yakazorwa nemafuta edhiziri.

Mupunga. 69. Dorn yebhushi remusoro wepamusoro wetsvimbo yekubatanidza.

d = D - 0,3;

d1 = D(-0,02/-0,03);

d2 = D(-0,09/-0,07);

d3 = D – 3;

D = piston piston nominal dhayamita.

Zvadaro kutsauka kubva pakuenzanisa kwemasanhu emakomba ebhushi uye musoro wezasi wetsvimbo yekubatanidza inodzorwa maererano nezvinodiwa zveunyanzvi. Muchiitiko ichi, kugadzirisa tsvimbo yekubatanidza haibvumirwi. Zvadaro, musoro wezasi wetsvimbo yekubatanidza inounganidzwa nemabhushi, chifukidzo uye mabhoti. Mabhoti anofanira kupinda mumakomba ane chiedza chinoputika kubva ku200-gram sando.

Iyo yekubatanidza tsvimbo yemafuta migero inogezwa uye inocheneswa nemhepo. Mapistoni anofanira kupiswa muOKS-7543 kabati yemagetsi kana mubhati remvura-oiri pane tembiricha ye80-90 madhigirii Celsius, yozobatanidzwa netambo yekubatanidza nepini yepiston mune vice.

Musangano wakaungana unoiswa pandiro yekudzora kuitira kuti piston inobata chero ipi zvayo pamusoro peplate. Iine gap rakaita seweji rinopfuura 0,1 mm pamusoro pehurefu hwe 100 mm (kuyerwa neprobe), kit inoparadzaniswa, zvikamu zvinotariswa, kukanganisa kunoonekwa uye kubviswa.

Iyo piston yepiston mumabhosi episton inogadziriswa nekiyi yechirimo. Usati waisa zvindori, tarisa taper yekunze kwavo kwekunze pane control plate uchishandisa sikweya.

Mhete dzakaiswa papiston ine dhayamita diki kumusoro (kumanikidza, undercut kumusoro) sere *